CNC Deburring machine

Laser oxide removal

Edge rounding

Heavy slag removal

DETAILS

CNC Deburring machine

Technical paramaters

| Model | HM-1000G-W | HM-1300G-W |

| Working width | 1000mm | 1300mm |

|

Processing thickness |

0.5-80mm |

0.5-80mm |

|

Number of flexible grinding rollers |

4D | 8D |

|

Feeding speed |

0.5-6m/min |

0.5-6m/min |

|

Minimum processing size |

50*50mm | 50*50mm |

| Machine weight | 2800KG | 4500KG |

Machine functions

1. It is used for deburring, chamfering of sharp edges and corners, surface polishing, etc. of batch workpieces cut by turret punching machines and laser cutting.

2. Can process stainless steel, carbon steel, aluminum, copper and other materials.

3. According to different materials, the conveying workbench can be equipped with vacuum adsorption and magnetic workbench.

The features of machine

1. Touch screen control interface, intuitive and visual

2. Thickened and stable body, high stability

3. Rotating brush grinding head with two positive and two negative positions, more comprehensive grinding

4. The brush roller grinding head can be replaced easily and quickly

5. Modular design, can be freely combined

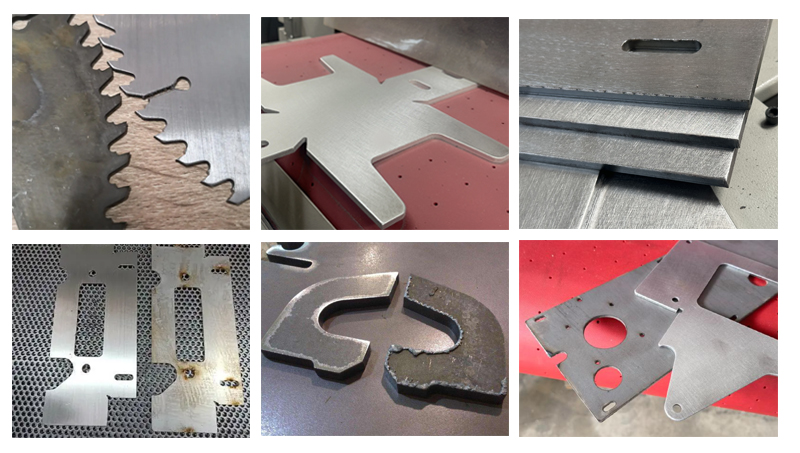

Samples