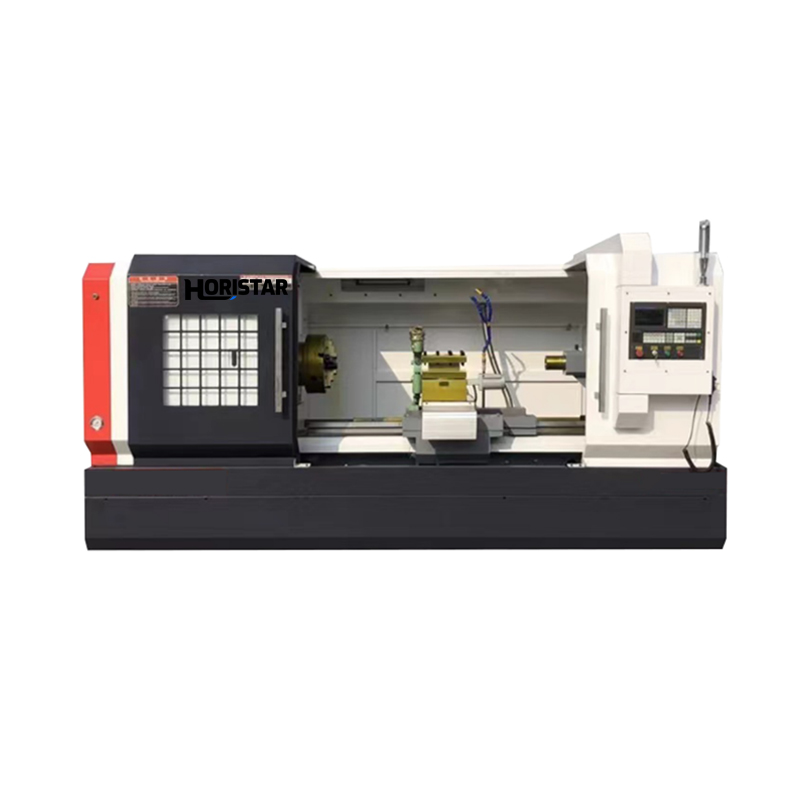

CNC Lathe Machine

High power spindle motor

Vertical electric tool holder

Adopt precision ball screw

Products

Products DETAILS

CNC Lathe Machine

Introduction

The bed of horizontal lathe is an integral structure with wide guide rails. After overclocking quenching and precision grinding, the rigidity of the machine tool is greatly improved, and the accuracy and service life of the machine tool are effectively guaranteed. The integral gearbox spindle unit adopts a high-power spindle motor with stepless speed regulation within the gear and a wide adjustment range, which can not only meet the requirements of thread finishing, but also achieve efficient cutting. The application of quenched precision ground gears and high-quality bearings ensures low noise and good sound quality of the machine tool. The spindle box adopts an external circulation lubrication cooling system, which not only reduces the temperature rise of the spindle, but also effectively ensures the cleanliness and lubrication of the spindle box. High-precision ball screws are used for the X.Z axis, and the large slide rail is attached with YT soft belt to improve the guiding accuracy and machine tool accuracy retention, effectively improving the service life of the machine tool. The machine tool is suitable for batch processing of castings and steel parts, and is also suitable for rough and semi-finishing.

Configuration

Mainly parameters

Item

Parameters

Model

CK6180*3000

Control system

980TB3i (Siemens for optional)

Motor

15KW

Converter

15KW

Chucks

φ400mm with 3 chucks

Tool holder

Electric tool holder

Automatic lubrication device

Item

Parameters

Maximum rotation diameter on machine

850mm

Maximum rotation diameter on tool holder

520mm

Maximum processing length

3000mm

Effective processing lenght

2850mm

Spindle through hole diameter

φ105mm

Spindle level

4-speed stepless transmission

Minimum movement unit of the carriage in Z direction

0.001mm/min

Minimum moving unit of the carriage in X direction

0.0005mm/min

Z axis travel

3000mm

X axis travel

420mm

X axis positioning accuracy

0.015mm

Z axis positioning accuracy

0.02mm

X axis repeat positioning accuracy

0.01mm

Z axis repeat positioning accuracy

0.01mm

20 Tailstock quill diameter

130mm

Tailstock sleeve taper hole

Morse 6

Tailstock sleeve maximum stroke

250mm

Repeat positioning accuracy of electric tool holder

0.002mm

Machine weight

5500KGS

Machine size

5400*1750*1720mm

Power supply

20KW/30A

Application

1. This machine tool can perform rough and fine machining of mechanical parts, and is particularly suitable for the automotive, military, machinery and other industries, and can perform efficient, large-scale, and high-precision machining of rotating parts.

2. This machine tool can process materials such as steel, cast iron and non-ferrous metals.

3. This machine tool is also suitable for turning small and medium batches of shaft and disk parts such as internal and external cylindrical surfaces, conical surfaces, threads, drilling, reaming and curved rotating parts.